Innovations

Hybrid Compressors

Multi-Stage, Rotating and Non-Rotating Hybridized Axial Compressor Module

Upwing’s hybrid multiphase subsurface compressors are used as a form of artificial lift for gas wells to increase wellbore drawdown at the compressor intake and pressure boosting at compressor discharge.

The increased gas production ranging from 20 to 150% from the use of a subsurface gas compressor in gas wells demonstrate the same effects of increased drawdowns by artificial lift in oil wells.

Benefits

Wide Operating Range

Upwing compressors are designed to have wide operating ranges to compensate for the flow and pressure fluctuations during the life of a conventional or unconventional gas well. Furthermore, due to straight flow path and large gaps between the stator and rotor blades, by design, the compressors can handle particles up to 200µm. Continuous testing is being conducted in Upwing’s flow loop to better characterize the compressors at higher levels of liquid content in the gas stream as well as larger particles to further optimize design.

Similar to ESP systems, a significant number of compressor stages can be stacked to reach the desired pressure ratios at given flows and temperatures.

Autonomous Control

The topside autonomous control system monitors in real time the health of Upwing’s compressor and adjusts the power and speed via the topside variable speed drive (VSD) to ensure the compressor is operating within the desired window to avoid surge conditions.

Liquid Loading Solution

The combination of Upwing compressors’ characteristics, such as increasing reservoir drawdown, accelerating the bottom hole gas velocity at the suction point and increasing the pressure and temperature of the gas at the discharge point as well as the gas velocity at the well bore, enables significant liquid carryover to the surface and postpones liquid loading without the use of the water pumps that are commonly used in gas wells today.

Compressor Topology

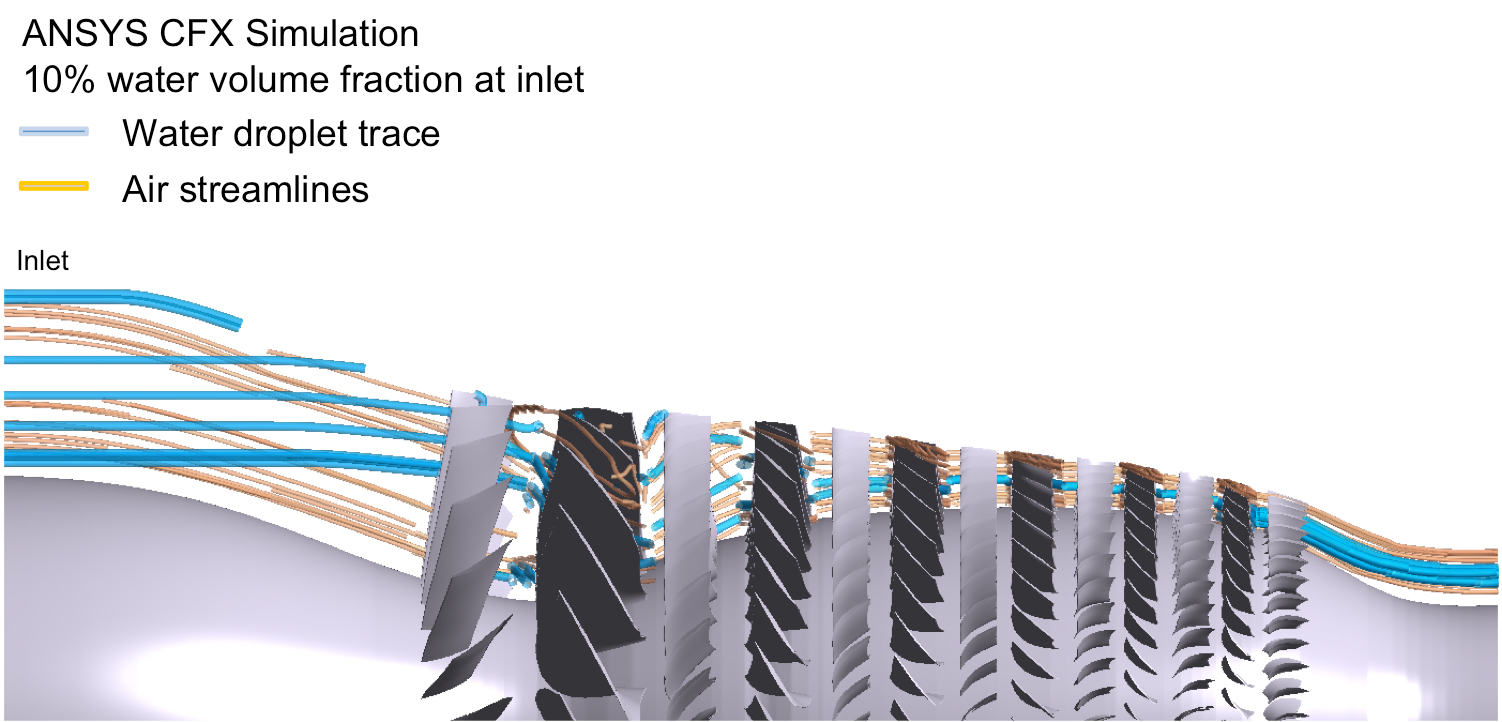

Upwing’s compressor topology is composed of multiple stages of rotating and non-rotating hybridized axial compressor blades.

See It In Action

The image on the right depicts water ingestion in a 6-stage axial compressor. Due to heavy density, water droplets travel toward the casing. Because of the straight flow channel and high kinetic momentum, water droplets follow gas streamlines.